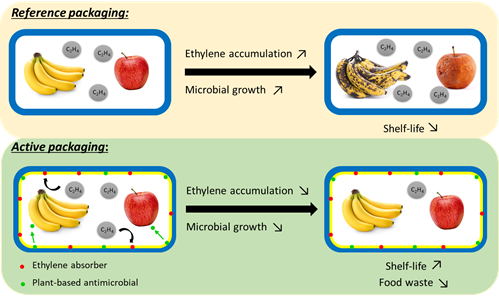

The project aims to develop new active packaging concepts comprising functionalities, such as ethylene removal and release of antimicrobials. Such packaging are necessary to extend the shelf-life of fruits and vegetables, such as tomatoes, apples and bananas. Such fruits spoil quickly due to microbial growth and an increased metabolic activity (due to ethylene accumulation) contributing to the generation of high amounts of food waste. In fact, fruits and vegetables have the highest wastages rates of food contributing to 45% of food waste, which shows the necessity to reduce the generation of fruit waste and to develop multifunctional packaging systems.

The FreshInPac project will focus on the development of a paper-based and a (bio)polymer-based packaging to extend the shelf-life of apples, bananas and tomatoes.

The project is divided in four parts, beginning with the development of new ethylene gas absorbers. The developed ethylene scrubbers as well as commercial ones will be incorporated in biopolymer films and coated on paper sheets. The ethylene-removal capacity of films and sheets will be verified by performing ethylene absorption kinetics.

In a second step, the project partners will select various plant-based antimicrobials that will be incorporated into biopolymer films and coated on paper sheets. The antimicrobial properties of prepared sheets will be evaluated by antimicrobial tests for selected bacteria, microbes and pathogens.

All these developments will be accompanied by the development of mathematical models and simulations to identify the most optimal packaging concept.

Once the optimal packaging concept has been identified, trays will be produced to pack the selected fruits. The efficiency of the developed trays will be tested by performing shelf-life tests on package fresh fruits. Besides, the recyclability and compostability of developed trays will be studied.

Finally, the developed packaging materials will be used to prepare packaging at interested SEMs of the user committee in order to study the compatibility of packaging materials with existing packaging machines.